how cement plant works

how cement plant works

How Cement Is Made

After the clinker is cooled, cement plants grind it and mix it with small amounts of gypsum and limestone Cement is so fine that 1 pound of cement contains 150 billion grains The cement is now ready for Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of Cement Extraction, Processing, Manufacturing Britannica

Concrete plant

A concrete plant, also known as a batch plant or batching plant or a concrete batching plant, is equipment that combines various ingredients to form concrete Some of these inputs include water, air, admixtures, sand, aggregate (rocks, gravel, etc), fly ash, silica fume, slag, and cement A concrete plant can have a variety of parts and accessories, including: mixers (either tilt drum or horizontal, or in sCement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering The Cement Manufacturing Process Thermo Fisher

Cement Production an overview ScienceDirect Topics

Abstract Cement production is an energyintensive process The cost of energy constitutes more than 60% of the cost of the cement; hence cement plants have to consider A cement plant consumes 3 to 6 GJ of fuel per tonne of clinker produced, depending on the raw materials and the process used Most cement kilns today use coal and petroleum coke as primary fuels, and to Cement

Cement Production: How Cement Is Manufactured

How Cement Is Made How We Make Our Cement Watch on 1 Mining the raw material Limestone and clay are blasted from rock quarries by boring the rock and setting off 96 行The key mass and energy flows processed through each main plant systems (eg cement plant, carbon capture unit, CO 2 conditioning, air separation unit, power plant Cement Plant an overview ScienceDirect Topics

Cement Plants located in United Kingdom The Global Cement Report

Switch to statistics view Cement plant locations and information on United Kingdom can be found below For full access to the database, purchase The Global Cement Report™, 14th Edition Purchase Summary Cement capacity (Mt) Integrated plants 11 Clinker plantsThe primary functions of a concrete manufacturing plant include aggregate feeding, in which sand and aggregates are fed into feeder bins Power feeding, meanwhile, is when cement, fly ash, and additives are added to the mix Water is used to bind cement evenly with the aggregatesHow Does Concrete Plant Work? Start A Blog

How many cement plants are producing in India 2020?

210 Large Cement Plants in India 2020 A total of 210 large cement plants account for a combined installed capacity of 410 MT in the country, whereas, 350 mini cement plants make up for the rest Of the Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kiln In this process, the chemical bonds of the raw materials are broken down and then they The Cement Manufacturing Process Thermo Fisher Scientific

How Cement is Made Cement Manufacturing Process

Stage 2: Grinding, Proportioning, and Blending The crushed raw ingredients are made ready for the cementmaking process in the kiln by combining them with additives and grinding them to ensure a fine homogenous mixture The composition of cement is proportioned here depending on the desired properties of the cement Generally, limestone is 80%, and the A cement is a binder, a substance used for construction that sets, hardens, and adheres to other materials to bind them together Cement is seldom used on itHow Cement Is Made? (Mega Factories Video) YouTube

How does the concrete batching plant work? Poyatos

A concrete batching plant is a machine that mixes concrete by using a rotating drum The machine creates the right mix of cement and water The drum rotates at high speeds, which allows the cement to be mixed with air and water at different rates, creating a homogeneous mixture It´s able to mix up to 5 cubic meters of concrete in one hourother factors Table 2 represents the cement plant locations and relevant information on Sri Lanka [8] Table 2 Cement plant locations in Sri Lanka [8] Group Name Company Name Facility Name Location Siam City Cement, PLC(SCCC)Group INSEE Cement (Lanka) Ltd Galle Cement Works Galle Siam City Cement, PLC(SCCC)GroupCement Industry in Sri Lanka JRTE

Here’s How a Concrete Batch Plant Works Concrete Questions

A concrete batch plant is a factory that stores the various constituent elements of concrete water, cement, aggregates, and additives in suitable tanks Then, it manufactures the custommade concrete at the request of each customer The concrete manufactured in the plant is produced in large quantitiesIn a modern works, the blended raw material enters the kiln via the preheater tower Here, hot gases from the kiln, As the cost of refractories is a major expense in operating a cement plant, kiln stoppages are avoided as far as possible As the meal passes through the burning zone, it reaches clinkering temperatures of about 1400 CManufacturing the cement kiln Understanding Cement

Cement Manufacturing Process JK Lakshmi Cement

This video answers many questions like सीमेंट कैसे बनता है? How to make cement? What is the process of making good cement?IConveniently for cement producers, switching to producing LC 3 only requires minimal changes to infrastructure in existing plants, making the operational transition straightforward and lowcost At How lowcarbon cement can benefit emerging

Cement plants in leading countries worldwide 2022

Get in touch with us now,Dec 12, 2022 In 2022, China had the most overall number of cement plants worldwide, with 875 plants reported China had 818 integrated plants and 57 grinding plantsCheck this video and learn how a concrete plant work Website: https://concretemixerwithpump/concretebatchingplantforsale/: market11@aimixgroupHow Does A Concrete Batch Plant Work? Belt Type Batching Plant

Cement Production: How Cement Is Manufactured CEMEX UK

2 Transporting the raw material Once the huge rocks have been fragmented, they are transported to the plant in dump trucks or by conveyor belt 3 Crushing The quarry stone is delivered through chutes to the crushers, where it is reduced by crushing or pounding to chunks approximately 1 ½ inches in size 4Cement is a capex Heavy Business The ROAs of a cement plant is close to 1 So a Cement plant with 5000 Crores of Capex can typically do a turnover of 5000 Crores only Hence it is important, that not only does the company set up a plant in the best market (which offers best prices), it should also ensure that cost of setting up the plant isUnderstanding How The Indian Cement Industry Works Alpha

How a cement plant works Holcim

How a cement plant works 1 Quarrying and blasting The raw materials that are used to manufacture cement are blasted from the quarry 2 Transport The raw materials are loaded into a dumper 3 Crushing and transportation The raw materials, after crushing, are transported to the plant by conveyor The plant stores the materials before they are1 When cement silo in bulk is working, the cement silo must be erected by special crane and then is placed on the concrete foundation prepared in advance Then the users should examine theHow to Operate the Cement Silo of Concrete Batching Plant

Concrete Batch Plant Work Components & Types of Concrete

When we talk about 1:3:6, it defines the ratio or parts of cement, fine and coarse aggregates Meaning the mix material has one part of cement, three parts of fines and six parts of coarse aggregates The proportion is by weight Types of concrete plants Concrete plants have been designed into different types by manufacturers to suitCement plant locations and information on India can be found below For full access to the database, purchase The Global Cement Report™, 14th Edition Purchase Summary Cement capacity (Mt) Integrated plants 172 Clinker plants 4Cement Plants located in India The Global Cement Report

- بحث في تأثير تعدين الذهب

- كسارة الحجر المحمولة للبيع سعر مصر

- شرکت خرد کردن گیاه

- أوقية الذهب كسارة يونيو

- مطاحن الكرة الذهبية الألمانية

- الرمل والحجر فصل الجهاز

- الحصى الكرة حجر صنع طاحونة

- تستخدم النباتات طحن

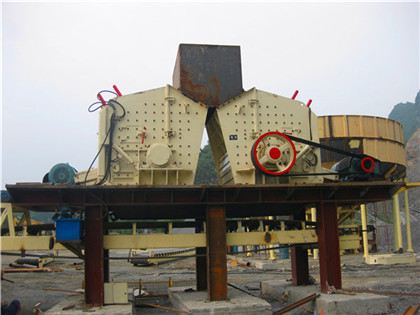

- كسارة صدمية كسارة متحركة لسحق الحجارة في هواهونغ

- محطم ريتسبرويت في جميع أنحاء العالم

- قائمة مصانع الاسمنت في إثيوبيا

- مصنعي الرمال الاصطناعية في نيجيريا

- إصلاح كسارة تأثير الدولوميت في أنغولا

- بيع معدات البوااقي في المانيا

- تكلفة مصر مصنع للاسمنت مصغرة

- الأسمنت مطحنة للبيع في العراق

- ما هي المعدات لسحق خام الحديد إلى ميكرون

- حيث مصنعي آلات طحن في الهند

- معدات تكسير الخط

- طحن الفحم في محطات الطاقة الحرارية

- مصنع مطحنة الكرة باكستان

- زينيث كسارة المحمولة

- شراء كسارات الغرانيت المستعملة في السعودية

- اتصالات محطم في كينيا

- معدات تعدين الذهب حلم

- التنتالوم إثراء النيوبيوم خام

- طحن الحبوب تصاميم مطاحن pdf

- كسارة القرص الصلب في الموقع

- مطحنة الكرة العملية الجافة

- مورد جيد لطحن الكرة الصغيرة مع خام النحاس التنافسي

- الرخام سعر مطحنة

- مصانع الشركة المصنعة محطم

- 220 tph آلة كسارة موريشيوس

- سعر آلة كسارة الحجر التلقائي

- مطحنة شبه منحرف مطحنة طحن الكاولين

- فک معایب سنگ شکن

- عملية استخراج الزنك

- ماكينات صناعية كبير

- ممكن اقتراح

- الغرانيت المصنعين صخرة محطم في الولايات المتحدة الأمريكية

- الاستثمار في أعمال المحاجر في غانا

- دراسة حول تكنولوجيا النانومصادم عن طريق كسر خلايا الخميرة

- pyb900 الصين مخروط محطم

- محطم قدرة صغيرة من النحاس يوميا 5

- jaypee طحن الاسمنت وحدة بانيبات

- من الفك كسارة تعمل

- در سیمان بالاست معدن

- المعلمات معدات مطحنة عمودية

- بحث عن الناقلات الجزئيه بالفراغ

- شتاوات ع الغربال

- المحجر باسير ماشينكواري باسير المحمول

- مطحنة الكرة علبة التروس Le1605

- التعدين كتلة بيع بولاوايو

- آلة صنع الرمل المتنقلة 1

- برای صفحه نمایش لرزش

- آلات طحن وسحق في مصنع الأسمنت

- غالبًا ما تحل محل جزء من الكسارة

- تشحيم مطحنة شبه منحرف متوسطة السرعة

- الماس طحن عجلة الصين

- يستخدم خام الحديد كسارة الفك للتوظيف مصر

- جنوب أفريقيا يؤدي معدات التعدين

- تغذية محطم أثر تغذية تغذية إيطاليا

- مزدوج منشأة طحن القرص في اندور

- تستخدم خط إنتاج تكسير الحصى

- فلز دستگاه فرز

- معدات التعدين حصة السوق

- مطحنة الكرة ريمون مطحنة شبه منحرف

- أوغندا كسارة صغيرة مخروط المصنعين الصين

- طرق تعدين ومعالجة الذهب الغريني

- معدات للبيع ثقيله سوق دبي كومستو

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت